In the early stages of product development and design, Tetra's team is ready to assist you in getting your product ready to manufacture.

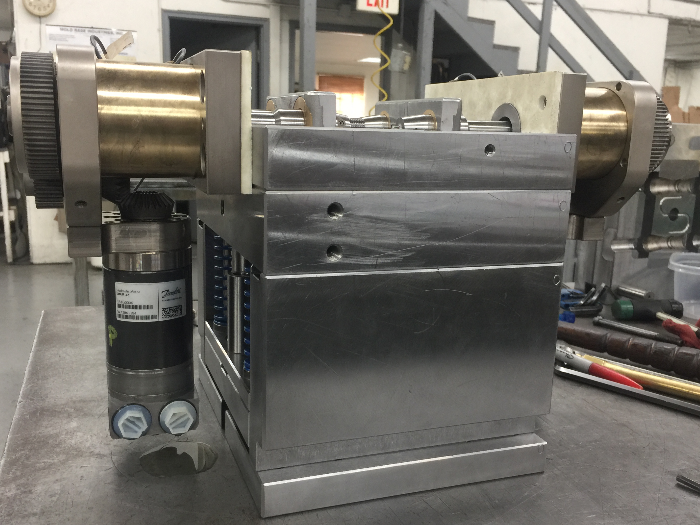

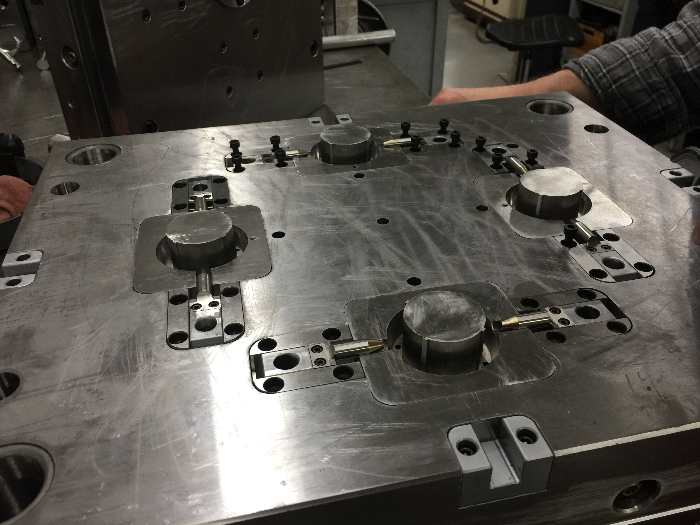

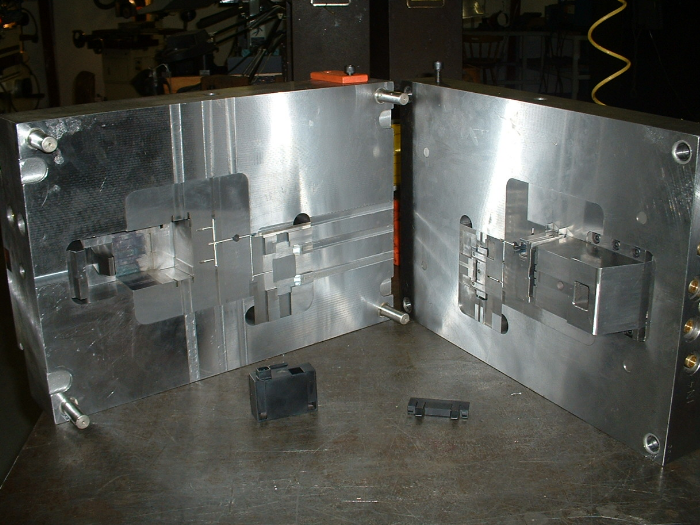

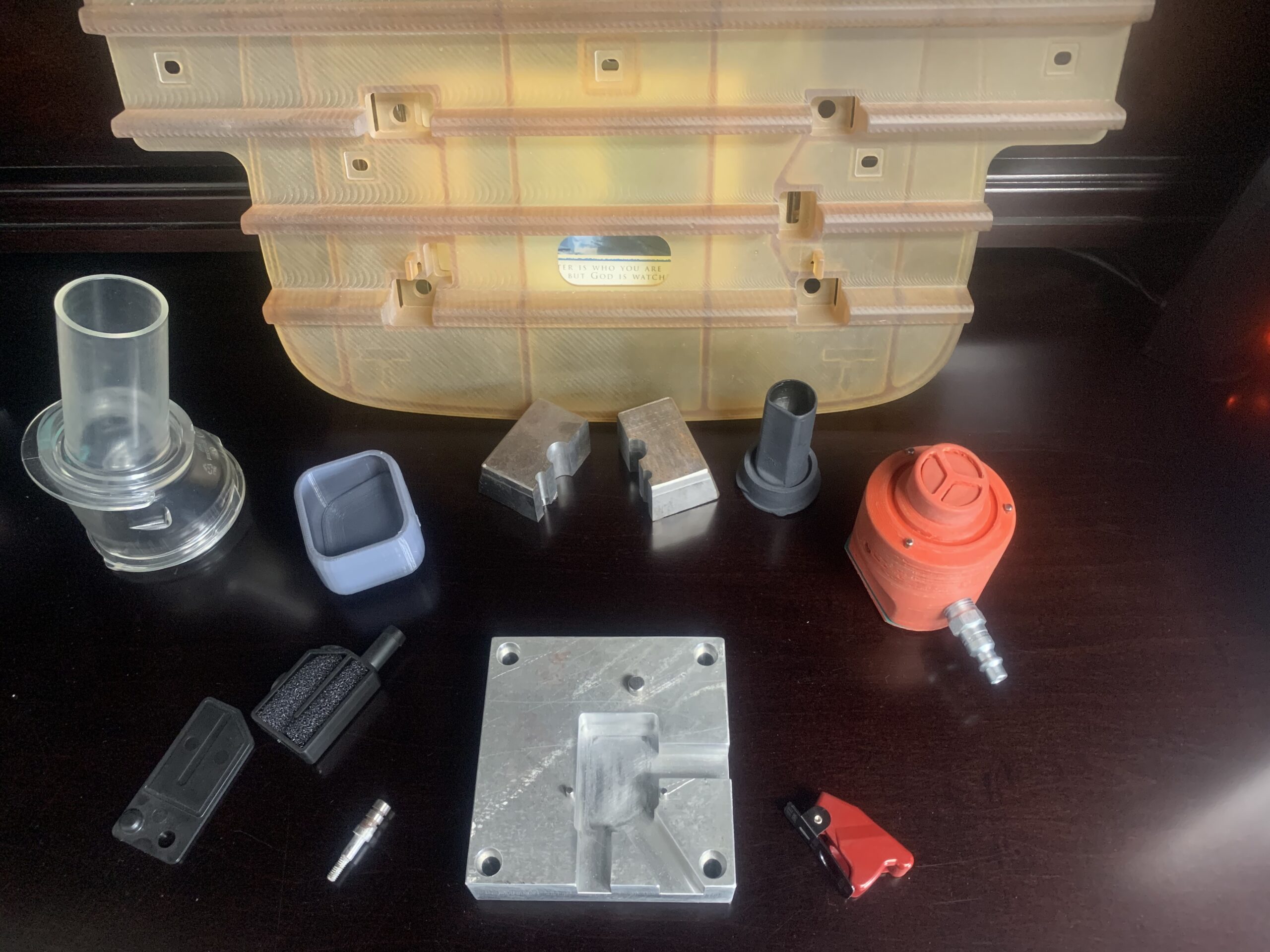

Our mold building division is a standalone operation that builds and repairs molds for internal use as well as for other molding companies, thermosets, thermoplastics and everything in-between.

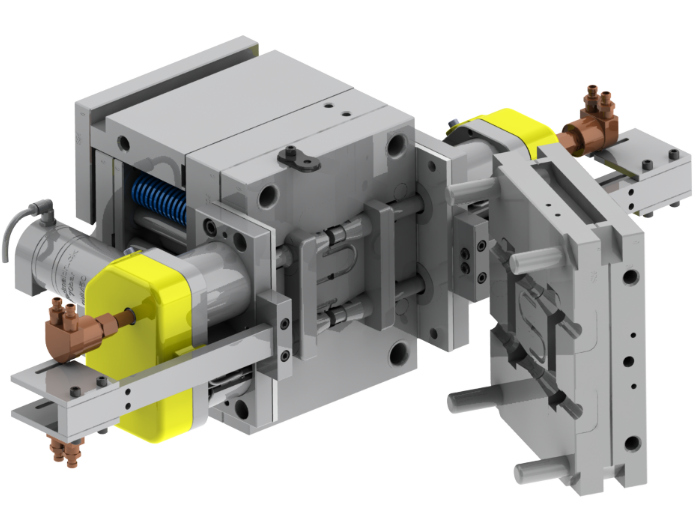

If your part requires insert molding/ over-molding we have the ability and the experience to take your parts from design through completion.

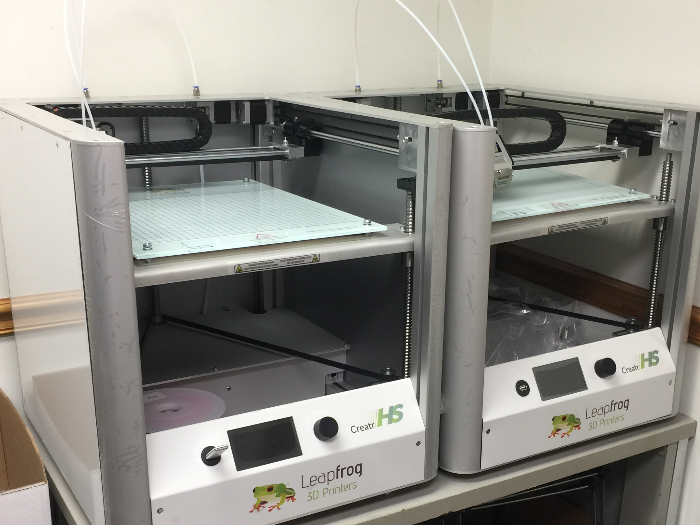

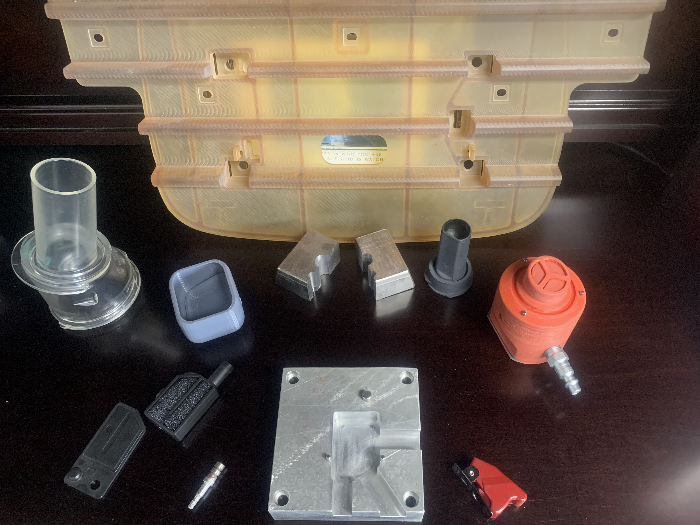

Tetra has a variety of in-house prototyping methods to verify your design. From 3-D printing & CNC machining to prototype molding, we have you covered.

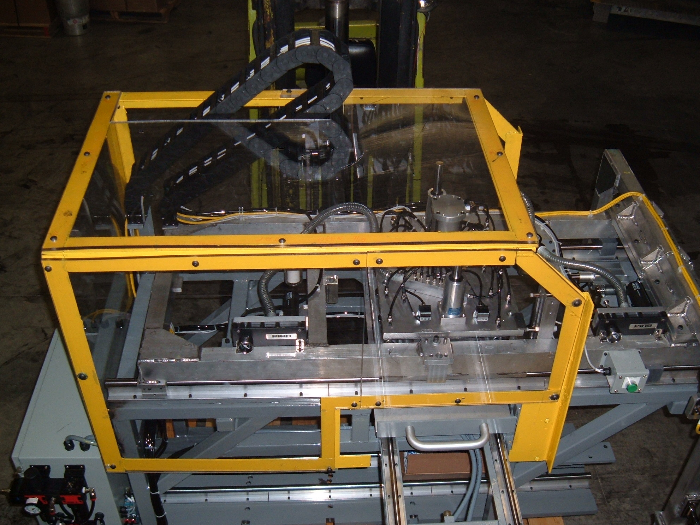

With both horizontal and vertical machines from 35 ton to 500 ton, we can produce your products out of a wide variety of materials and mold types.

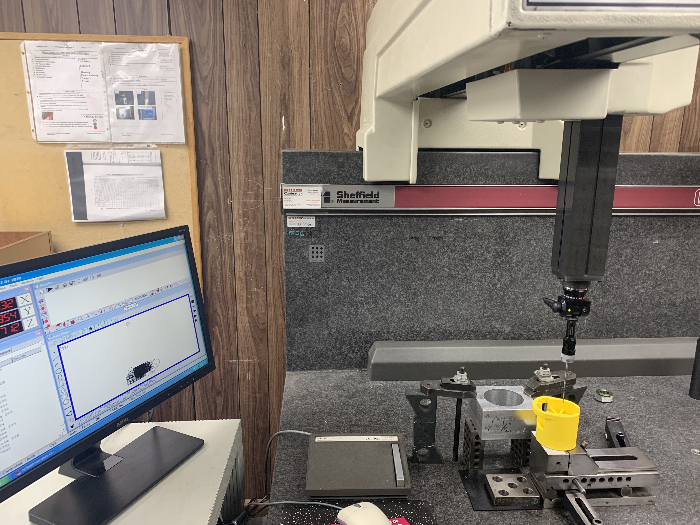

All of our processes are based on producing a quality product. From IATF certification, SPC process control, and continuous improvement we put quality first in all aspects of our operation.

From single part to multi-step sub assemblies, we have experience in machining all types of metal and plastic materials.

With our background in machining, mold building and insert molding, some of our customers prefer Tetra to make the inserts to use in their insert molded products.

If you're looking for assistance on your next project, let us know we're ready to help.